Nieuwe fabricage-enquête identificeert “capabiliteitskloof” voor bedrijven die streven naar productiviteit en innovatie

- Rapport ‘State of Product Development & Hardware Design 2020’ stelt vast dat bedrijven tekortschieten op belangrijke gebieden van productiviteit en innovatie

- Fabrikanten zeggen dat hun topprioriteit voor verbetering het minimaliseren van de tijd die wordt besteed aan niet-ontwerpgerelateerde activiteiten en overheadkosten is

- Meer dan 80% van de productontwikkelingsprofessionals heeft problemen met het vinden of openen van de juiste versie van ontwerpgegevens

BOSTON– (BUSINESS WIRE) – (NASDAQ: PTC) In een nieuw industrieonderzoek onder bijna 1.000 productontwikkelingsprofessionals van over de hele wereld zegt 80% van de ondervraagde productiebedrijven dat ze de tijd moeten minimaliseren die hun technische teams besteden aan niet-ontwerpgerelateerde activiteiten, zoals datamanagement en administratieve taken. Het State of Product Development & Hardware Design 2020-rapport onderzoekt de ongekende uitdagingen waarmee productontwikkelingsteams worden geconfronteerd tijdens de coronaviruspandemie en identificeert significante kansen voor verbetering.

New Manufacturing Survey Identifies “Capabilities Gap” for Companies Striving for Productivity and Innovation

- “State of Product Development & Hardware Design 2020” Report Finds That Companies Are Falling Short in Key Areas of Productivity and Innovation

- Manufacturers Say their Top Priority for Improvement is Minimizing Time Spent on Non-Design Related Activities and Overhead

- More than 80% of Product Development Professionals Have Trouble Finding or Accessing the Correct Version of Design Data

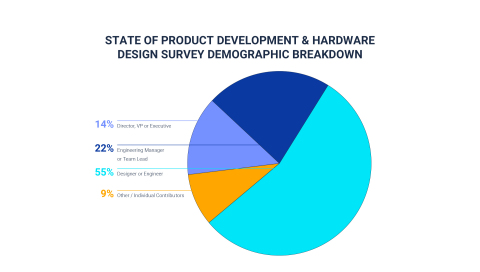

BOSTON–(BUSINESS WIRE)– (NASDAQ: PTC) In a new industry survey of nearly 1,000 product development professionals from around the world, 80% of manufacturing companies surveyed say they need to minimize the time their engineering teams spend on non-design related activities, such as data management and administrative tasks. The State of Product Development & Hardware Design 2020 report explores the unprecedented challenges facing product development teams during the coronavirus pandemic and identifies significant opportunities for improvement.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20200910005995/en/

Commissioned by PTC’s Onshape offering, The State of Product Development & Hardware Design, addresses the biggest challenges facing today’s design & manufacturing teams. (Graphic: Business Wire)

The independent industry survey, commissioned on behalf of PTC’s Onshape® Software as a Service (SaaS) product development platform, concludes that manufacturing companies risk missing strategic goals due to cumbersome processes and outdated design tools/technologies that are not suited for a flexible and remote workforce. In the vast majority of the 15 product development categories asked about in the survey, companies reported a disconnect between what they believe are capabilities that are critical for driving productivity/innovation and their actual performance in each of these areas.

“This report offers a fascinating look at companies’ self-reported strengths and weaknesses in the product development process,” says Jon Hirschtick, Executive Vice President and President of SaaS, PTC. “The capabilities gap between where engineering teams say they want to be and where they believe they are right now is a reminder that successful companies have to be hyper-agile. The need to constantly re-evaluate existing tools and processes is especially vital to not just surviving but thriving during unpredictable times.”

Notable product development capability gaps reported in the survey include:

- Minimizing time spent on non-design related activities and overhead (82% of respondents rated as critical for success – 41% rated their current capabilities as good or excellent)

- Ability to monitor activity/progress at any stage in the design process without meetings, emails or calls (77% rated as critical for success – 43% rated their current capabilities as good or excellent)

- Satisfaction with simulation tools (75% rated as critical for success – 43% rated their current capabilities as good or excellent)

- Satisfaction with PDM or PLM tools (69% rated as critical for success – 40% rated their current capabilities as good or excellent)

The report also explores companies’ top priorities for improvement in the product development process, as well as the obstacles blocking these goals. The most urgent priorities include resolving version control issues, increasing earlier communication and collaboration across the company, and making computer-aided design (CAD) data less siloed and more available throughout the design process.

Amid extended work-from-home policies due to the COVID-19 pandemic, the report concludes that cloud-based productivity tools give companies more confidence in their ability to support remote work. Of companies that score themselves highest in productivity, 87% state they are now able to effectively support work from home. With a cloud-based CAD and data management platform, companies can drive earlier collaboration and boost productivity and innovation.

To read a full copy of the report, please visit https://Onshape.com.

About PTC (NASDAQ: PTC)

PTC enables global manufacturers to realize double-digit impact with software solutions that enable them to accelerate product and service innovation, improve operational efficiency, and increase workforce productivity. In combination with an extensive partner network, PTC provides customers flexibility in how its technology can be deployed to drive digital transformation – on premises, in the cloud, or via its pure SaaS platform. At PTC, we don’t just imagine a better world, we enable it.

PTC, Onshape, and the PTC logo are trademarks or registered trademarks of PTC Inc. and/or its subsidiaries in the United States and other countries.

View source version on businesswire.com: https://www.businesswire.com/news/home/20200910005995/en/

Contacts

PTC

Corporate Communications

Greg Payne