KANEKA: “Development of Polymer Synthesis Technology by Microorganisms using CO2 as Direct Raw Material” selected as a NEDO Green Innovation Fund Project”

TOKYO–(BUSINESS WIRE)– Kaneka Corporation (Headquarters: Minato-ku, Tokyo; President: Minoru Tanaka; hereinafter “Kaneka”), Bacchus Bio innovation Co., Ltd (Headquarters: Kobe-city, Hyogo; President: Mikio Tanji; hereinafter “Bacchus”), JGC Holdings Corporation (Headquarters: Yokohama-city Kanagawa; Chairman and CEO: Masayuki Sato; hereinafter “JGC HD”), and Shimadzu Corporation (Headquarters: Kyoto-city, Kyoto; President: Yasunori Yamamoto; hereinafter “Shimadzu”) have announced that the proposal of a joint project, “Development of Polymer Synthesis Technology by microorganisms using CO2 as direct raw material (hereinafter referred to as ‘the Project’)” had been selected by the “Green Innovation Fund Project*1 / Promotion of Carbon Recycling Using CO2 from Biomanufacturing Technology as a Direct Raw Material” as a planned implementation sponsored by the New Energy and Industrial Technology Development Organization (NEDO).

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20230331005155/en/

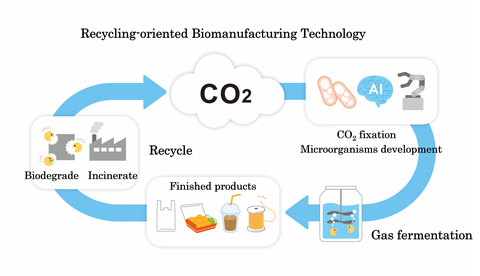

(Figure 1) Recycling-oriented Biomanufacturing Technology (Graphic: Business Wire)

This project will contribute to the realization of carbon recycling in the “Green Growth Strategy Through Achieving Carbon Neutrality in 2050” formulated by the Ministry of Economy, Trade and Industry with related ministries and agencies on December 25, 2020 (revised on June 18, 2021). The goal of the project is to realize recycling-oriented biomanufacturing technology that does not depend on fossil resources by developing microorganisms that produce biodegradable polymers from CO2 and developing production process technology, combining the knowledge and technology that the four companies have cultivated over the years.

During the project period (FY2023 to FY2030), the following three themes will be addressed.

- Establishment of a gas fermentation biofoundry*2 using CO2 as a raw material (Bacchus and Shimadzu)

- Development and improvement of biopolymer-producing microorganisms (Kaneka)

- Development and demonstration of production technology using microorganisms capable of producing substances from CO2 (Kaneka, JGC HD, Shimadzu)

[ Kaneka ] https://www.kaneka.co.jp/en/

Kaneka is the first company in the world to successfully commercialize KANEKA Biodegradable Polymer Green PlanetTM (“Green Planet”), which is produced by microorganisms from vegetable oil and other raw materials. In this project, based on the synthetic microbiology and polymer production, processing technologies it has cultivated to date, Kaneka will develop new microorganisms that produce Green Planet directly from CO2, and will also launch a semi-commercial plant to conduct production demonstration for Green Planet industrialization. In addition, we will lead this project as the managing company.

[ Bacchus ] https://www.b2i.co.jp/

Bacchus is a data-driven biofoundry company. Bacchus aims to drastically shorten the breeding time of smart cells*3 by upgrading the breeding platform consolidating its proprietary technologies. By utilizing its own digital technology, Bacchus will design cells optimized for gas fermentation and create a variety of species. In addition, they will introduce and utilize data from a high-throughput evaluation system jointly developed with Shimadzu, and aim to build an “Integrated Biofoundry*4” that will provide one-stop service from microbial breeding to process development with JGC HD.

[ JGC HD ] https://www.jgc.com/en/

JGC HD has a profound knowledge of the safe gas handling of gases including hydrogen gas and process scale-up cultivated through its EPC (Engineering, Procurement, and Construction) business in the oil and gas fields, as well as in optimized culture tank design technology in the life science field. In this project, JGC HD will develop and scale-up a safe handling system for mixed gases containing CO2, H2, and O2 and a highly efficient gas fermentation process in addition to establishing an “Integrated Biofoundry” with Bacchus which will provide a one-stop service from microbial breeding to process development.

[ Shimadzu ] https://www.shimadzu.com/

Shimadzu, with the aim of solving social issues, has accumulated a variety of know-how by providing analytical measurement and robotics technologies to a wide range of fields and data analysis technologies using AI-based systems. In this project, Shimadzu will work on the development of high-speed productivity evaluation technology, which is indispensable for the construction of a biofoundry. Shimadzu will also develop an evaluation system to measure gas fermentation in the semi-commercial plant which is to be constructed as part of the project and support safe and highly efficient fermentation.

*1. A project to support companies and others working on management issues toward Japan’s “Carbon Neutrality in 2050,” from R&D and demonstration to social implementation by FY2030. The program covers 14 fields: transportation/manufacturing-related industries including carbon recycling/materials industries, energy-related industries, and home/office-related industries.

*2. Biofoundry: Microorganism development platform that creates microorganisms with designed functions to efficiently produce useful substances

*3. Smart cell: A cell that is highly designed and has an enhanced ability to efficiently produce the desired substance

*4. Integrated Biofoundry: A one-stop biomanufacturing platform that provides everything from microbial breeding to process development

View source version on businesswire.com: https://www.businesswire.com/news/home/20230331005155/en/

Contacts

KANEKA CORPORATION

Investors & Public Relations Department

Chika Harada

Info_Pro@kaneka.co.jp