Humidity Control Systems Using Dry Fog in SMT Processes from IKEUCHI

Humidity control systems using Dry Fog not only preventing static electricity in SMT processes but also significantly slashing CO2 emissions and energy costs.

OSAKA, Japan–(BUSINESS WIRE)– H. IKEUCHI & CO., LTD., a Japanese spray nozzle manufacturer, has embarked on a global campaign to introduce humidity control systems powered by Dry Fog technology. These systems not only effectively mitigate static electricity issues in surface-mount technology (SMT) processes but also significantly slash CO2 emissions and energy costs.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20231114812827/en/

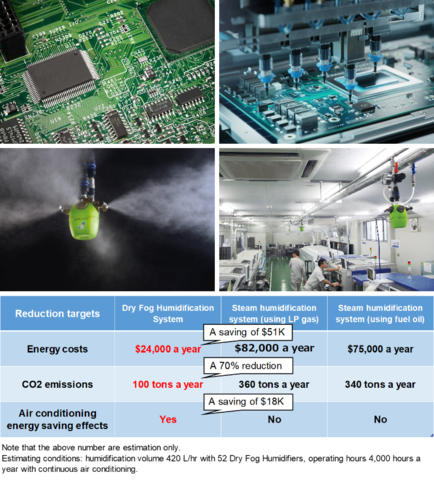

Each individual photo available upon request; IKEUCHI offers humidity control systems using Dry Fog that not only prevent static electricity in SMT processes but also significantly slash CO2 emissions and energy costs. (Graphic: Business Wire)

“Dry Fog,” generated by specialized spray nozzles uniquely developed by IKEUCHI, consists of ultrafine water droplets, each measuring 10 μm or less in diameter. What makes it stand out is that these minuscule droplets don’t burst upon contact with objects; instead, they bounce off, keeping products and equipment completely dry. This exceptional feature makes the system optimal for use in electronics manufacturing, particularly in the SMT processes, where wetness is a concern.

Upon being sprayed from the nozzle, Dry Fog swiftly disperses into the air, effectively increasing humidity levels. This ensures an optimal humidity environment, even in spacious manufacturing facilities, preventing problems arising from dryness and static electricity in the SMT processes. These problems include electrostatic discharge (ESD) damage, pick and place errors during chip mounting, inconsistent solder print quality, airborne particles sticking to products, and operator discomfort due to low humidity. All of these known problems can be averted by introducing the Dry Fog humidity control systems, leading to enhanced quality and work efficiency.

Furthermore, the Dry Fog humidity control systems significantly reduce environmental impact. Switching from conventional steam humidifiers that rely on heavy fuel oil to the Dry Fog remarkably slashes CO2 emissions and substantially saves energy costs. In fact, there have been successful cases where Dry Fog reduced CO2 emissions by 70% and delivered annual energy cost savings of $50,000 per year.

Prior to recommending a system, our dedicated sales representatives perform on-site evaluations and engage in thorough discussions with customers. This collaborative approach ensures the design of an optimal humidity control system tailored to each site.

Leveraging our global network and the proven success we have achieved in numerous countries, IKEUCHI is committed to assisting in solving issues faced by customers and contributing to the SDGs in each country.

Network: U.S., Europe, China, Taiwan, Indonesia, Thailand, Japan.

View source version on businesswire.com: https://www.businesswire.com/news/home/20231114812827/en/

Contacts

Yoshikazu Ueno

H. IKEUCHI & CO., LTD.

overseas@kirinoikeuchi.co.jp