Een grote sprong voorwaarts in brandstofceltechnologie door NTHU

HSINCHU, Taiwan-(BUSINESS WIRE)-Wetenschappers worstelen al lang met de ontwikkeling van hoogwaardige brandstofcellen als milieuvriendelijke energiebron in elektrische voertuigen. Prof. Chen Tsan-Yao van het Department of Engineering and System Science (National Tsing Hua University, Taiwan) heeft echter onlangs voor een belangrijke doorbraak gezorgd door succesvol gebruik te maken van ultrasone golven om kleine groeven in het oppervlak van verschillende materialen te maken, die in combinatie met een platinakatalysator op atomaire schaal kunnen worden gebruikt om de efficiëntie van de alkalische brandstofcellen (AFC’s) te verdubbelen.

Deze katalysator op atomaire schaal verhoogt de zuurstofreductie (kathode reactie) van de huidige intensiteit met een factor tien, zonder degradatie gedurende acht maanden van ononderbroken werking, terwijl de productiekosten met 90 procent worden verlaagd; dergelijke cellen hebben een levensduur van twee tot drie jaar.

A Great Leap Forward in Fuel Cell Technology Made at NTHU

HSINCHU, Taiwan–(BUSINESS WIRE)– Scientists have long been struggling to develop high-performance fuel cells as environmentally friendly power in electric vehicles. However, Prof. Chen Tsan-Yao of the Department of Engineering and System Science (National Tsing Hua University, Taiwan) has recently made a major breakthrough by using ultrasonic waves to make tiny grooves in the surface of various materials, which in conjunction with an atomic-scale platinum catalyst can be used to double the alkaline fuel cells (AFCs) efficiency.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20190507005508/en/

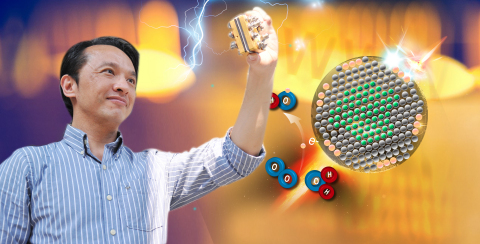

Prof. Chen Tsan-Yao recently developed a way of using ultrasonic waves to make tiny grooves on a metal surface, which in conjunction with an atomic-scale platinum catalyst can be used to double the efficiency of alkaline fuel cells. (Photo: National Tsing Hua University)

This atomic-scale catalyst increases the oxygen reduction (cathode reaction) current intensity by tenfold, with no degradation for eight months of continuous operation, while reducing the production cost by 90 percent; such cells have a lifespan of two to three years. This groundbreaking research has been published and selected as a focus paper of Energy Materials in the February issue of Nature Communications. Prof. Chen said that he is currently developing a quantum-size-correlation in catalyst for making cells even cheaper and more efficient.

Exploring the boundary in atomic scale

A fuel cell is a power generation device to convert chemical energy into electrical energy. AFCs are safer and more efficient than acid batteries, and thus are widely used in spacecraft and satellites. The catalyst is the key component in fuel cell performance. Prof. Chen said that there are many factors affecting the efficiency of the catalyst, especially size. At the same volume, the smaller the catalyst particles, the larger the surface area, and the higher the performance. However, if the particles are too small, they become unstable and rapidly lose their efficiency. Thus, Chen’s challenge was to find a way to reduce size and increase stability.

Inspired from the love of coffee soda

Chen said that coffee soda inspires him in the strategies. In 2016, while chatting with a coffee shop owner, he discovered that depending on the order in which the coffee and soda are poured into the glass, the sweetness, taste, and amount of bubbles are very different. As a result, he had his research assistants reverse the order in crystal growth. Unlike the traditional method, they add new materials every ten seconds and stop the reaction in only seconds, which results in the Pt trimer catalysts.

Reduced cost, increased efficiency, and extended lifespan

Not surprisingly, Chen’s students initially had some doubts about his unorthodox approach. With hundreds of failures, they finally made the Pt trimer catalysts which remained stable while maintaining high activity in AFCs. Chen said that the amount of platinum used in his atomic catalyst is only 1%, compared to 35% for the average commercial catalyst; and the mass current density is increased by 30 times.

View source version on businesswire.com: https://www.businesswire.com/news/home/20190507005508/en/

Contacts

Media contact:

Holly Hsueh

Executive Officer, Division of Public Affair

National Tsing Hua University

Tel: (886)3-5162006

Email: hoyu@mx.nthu.edu.tw